Our Services

-

27 Years Experience

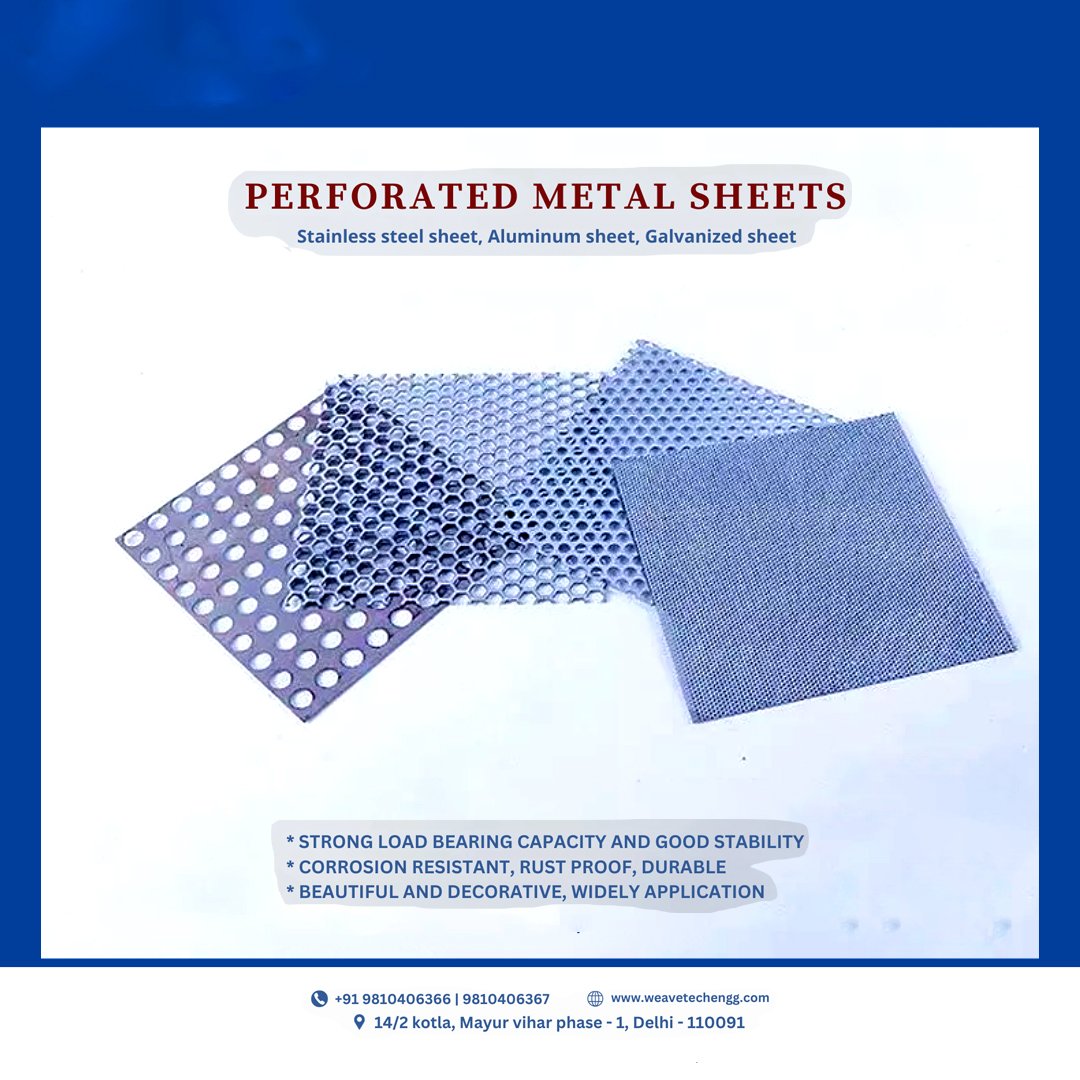

We’re Committed to Perforated Metal Sheets Excellence

Weave Tech Engineers is a leading company specializing in providing innovative engineering solutions across various industries. Established with a commitment to excellence, Weave Tech Engineers has built a reputation for delivering high-quality products and services tailored to meet the unique needs of its clients.

Learn More

GI Perforated Sheets

Metal Sheets- Experience:27 Years

- E-mail:inquiry@weavetechengineers.com

- Phone:098104 06366

- Location:

Mayur Vihar Phase-1

New Delhi, 110091

GI Perforated Sheets: Unraveling the Versatile Applications and Benefits

When it comes to diverse applications across industries, GI Perforated Sheets stand as a paragon of adaptability and functionality. These sheets, crafted from galvanized iron, undergo a meticulous manufacturing process involving precise perforations that render them invaluable in various sectors. In this comprehensive guide, we delve into the myriad applications, benefits, and distinctive features that make GI Perforated Sheets an indispensable material across industries worldwide.

GI Perforated Sheets

GI Perforated Sheets are meticulously engineered metal sheets crafted from galvanized iron. They undergo a specialized process of perforation, where precise holes or patterns are created. These sheets come in a range of shapes, sizes, and perforation patterns to suit diverse industrial requirements. The perforations, typically round, square, or slotted, offer remarkable versatility, allowing for specific functionalities across sectors.

Applications Across Industries

Construction IndustryIn the construction domain, GI Perforated Sheets find extensive use due to their durability, strength, and versatility. These sheets serve multiple purposes, including: Facade Cladding: Used in architectural applications for aesthetic appeal while providing weather resistance.

Acoustic Panels: Employed in building interiors for noise reduction while maintaining airflow.

Safety Barriers: Used as sturdy and resilient safety barriers in construction sites.

Automotive Sector

In the automotive industry, GI Perforated Sheets play a pivotal role owing to their lightweight yet robust nature. Some common applications include:Grilles: Used in automobile grilles due to their ability to allow airflow while offering protection.

Exhaust Systems: Applied in exhaust systems to manage emissions effectively. Agricultural Applications

GI Perforated Sheets serve crucial purposes in agriculture:

Sieving and Sorting: Utilized in agricultural machinery for sieving and sorting operations.

Ventilation: Applied in greenhouse structures for proper ventilation, ensuring optimal growth conditions for crops.

HVAC Systems

The Heating, Ventilation, and Air Conditioning (HVAC) industry

leverages GI Perforated Sheets for various functions:

Air Ventilation: These sheets facilitate airflow in HVAC systems

while maintaining structural integrity.

Filtration: Used in air filtration systems due to their perforated

design, enabling efficient filtration.

Benefits of GI Perforated Sheets

The galvanization process imparts GI Perforated Sheets with exceptional durability, making them resistant to corrosion, rust, and wear. This longevity ensures prolonged usage even in demanding environments, enhancing cost-effectiveness.

Versatility in Design

The ability to customize perforation patterns and sizes allows for

tailored designs, catering to specific industrial needs. Manufacturers

can create perforated sheets with varying hole diameters, shapes, and

layouts, ensuring unparalleled adaptability.

Optimal Functionality

The perforated design of these sheets ensures optimal functionality

across applications. Whether it's for airflow, filtration, or structural

support, GI Perforated Sheets offer unparalleled performance, making

them indispensable across industries.

GI Perforated Sheets epitomize adaptability and functionality, serving as indispensable components across diverse sectors. Their durability, versatility in design, and optimal functionality make them a preferred choice for various applications in construction, automotive, agriculture, HVAC, and beyond. As industries continue to evolve, the unmatched utility of GI Perforated Sheets solidifies their position as an essential material in the modern industrial landscape.