Our Services

-

27 Years Experience

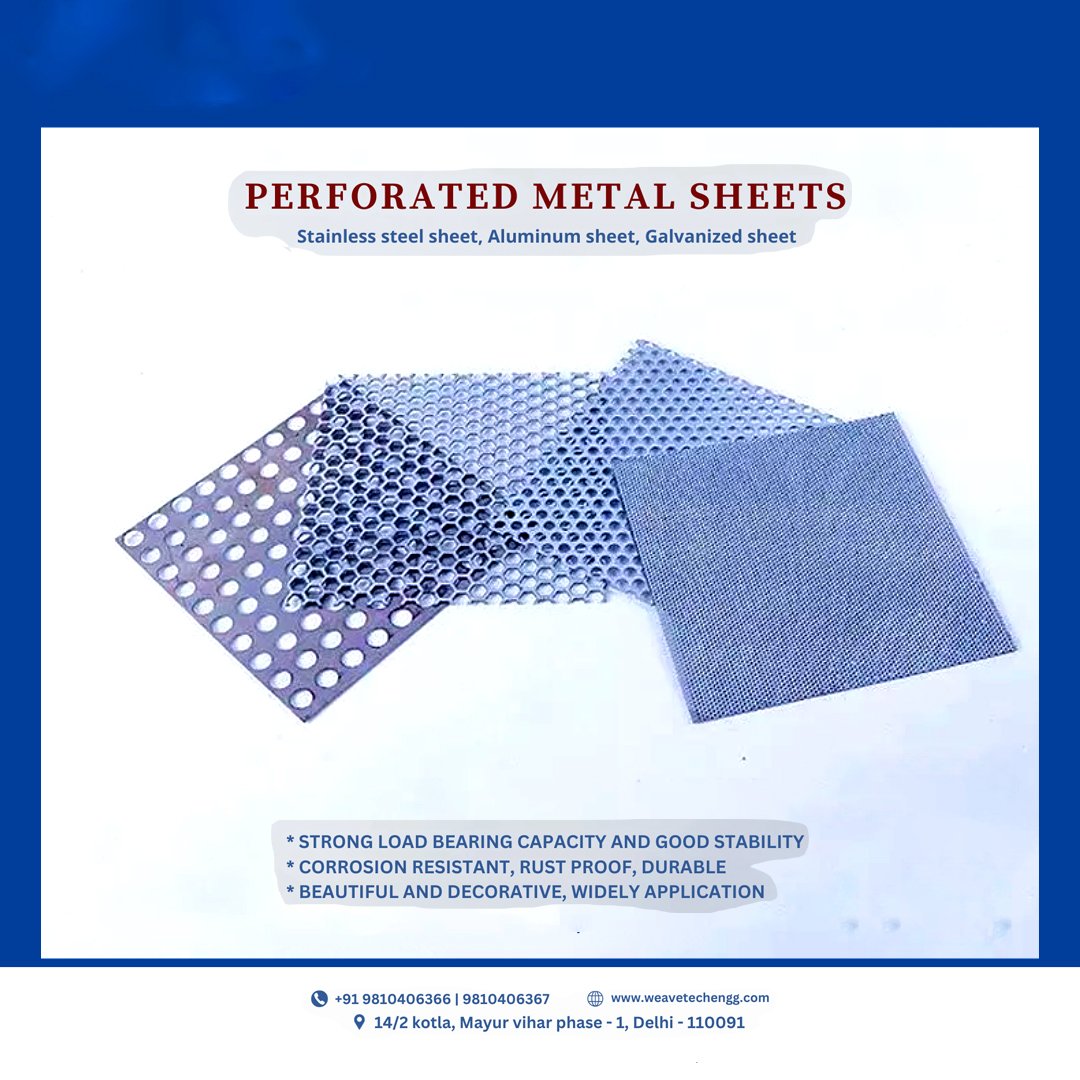

We’re Committed to Perforated Metal Sheets Excellence

Weave Tech Engineers is a leading company specializing in providing innovative engineering solutions across various industries. Established with a commitment to excellence, Weave Tech Engineers has built a reputation for delivering high-quality products and services tailored to meet the unique needs of its clients.

Learn More

Mild Steel Perforated Sheet

Metal Sheets- Experience:27 Years

- E-mail:inquiry@weavetechengineers.com

- Phone:098104 06366

- Location:

Mayur Vihar Phase-1

New Delhi, 110091

Mild Steel Perforated Sheet

Mild steel perforated sheets are versatile and widely used materials in various industries due to their exceptional properties. These sheets are manufactured from high-quality mild steel, featuring precise perforations that offer unique functionalities across diverse applications.

Composition and Manufacturing Process

Mild steel, renowned for its durability and strength, constitutes the base material for perforated sheets. These sheets are crafted through a meticulous manufacturing process involving precise punching or drilling of holes in the steel material. The perforations, available in various shapes and sizes, are strategically designed to meet specific industrial requirements.

Properties and Advantages

1. Durability:Mild steel perforated sheets are known for their exceptional durability, making them ideal for applications requiring robust materials. The inherent strength of mild steel ensures longevity, even in harsh environments.

2. Versatility:

These sheets offer remarkable versatility due to the range of perforation options available. With varied hole shapes and sizes, they cater to different functionalities, including filtration, ventilation, screening, and decorative purposes.

Enhanced Air and Light Flow:

The perforations in mild steel sheets facilitate improved air circulation and light transmission. This characteristic is particularly advantageous in applications where proper ventilation or visibility is crucial.

Customizability:

Manufacturers provide customization options concerning hole patterns, shapes, and sheet dimensions, allowing users to tailor the perforated sheets according to their specific project requirements.

Applications Across Industries

1. Construction:In construction projects, these sheets are utilized for facades, screens, partitions, and noise reduction elements due to their durability and aesthetic appeal.

2. Automotive:

The automotive sector employs perforated sheets for radiator

grilles, speaker covers, and air filtration components owing to

their excellent airflow properties.

3. Industrial Filtration:

Mild steel perforated sheets serve as efficient filtration mediums in

industries such as food processing, chemical, and pharmaceutical, where

precision filtration is imperative.

4. Decorative Purposes:

Their aesthetically pleasing patterns and customizable designs make

these sheets a popular choice for architectural and interior design

applications.

Maintenance and Care Tips

To ensure prolonged durability and optimal performance of mild steel

perforated sheets, regular maintenance and proper care are essential.

Some essential tips include:

Cleaning: Regularly clean the sheets using mild detergents to remove

dust and debris.

Rust Prevention: Apply appropriate coatings or treatments to prevent

corrosion and rust formation.

Inspections: Periodically inspect the sheets for damages or signs of

wear and tear, addressing any issues promptly.

Mild steel perforated sheets are indispensable materials that offer a myriad of benefits across various industries. Their durability, versatility, and customizable nature make them a preferred choice for numerous applications, providing efficient solutions and enhancing functionality.