Our Services

-

27 Years Experience

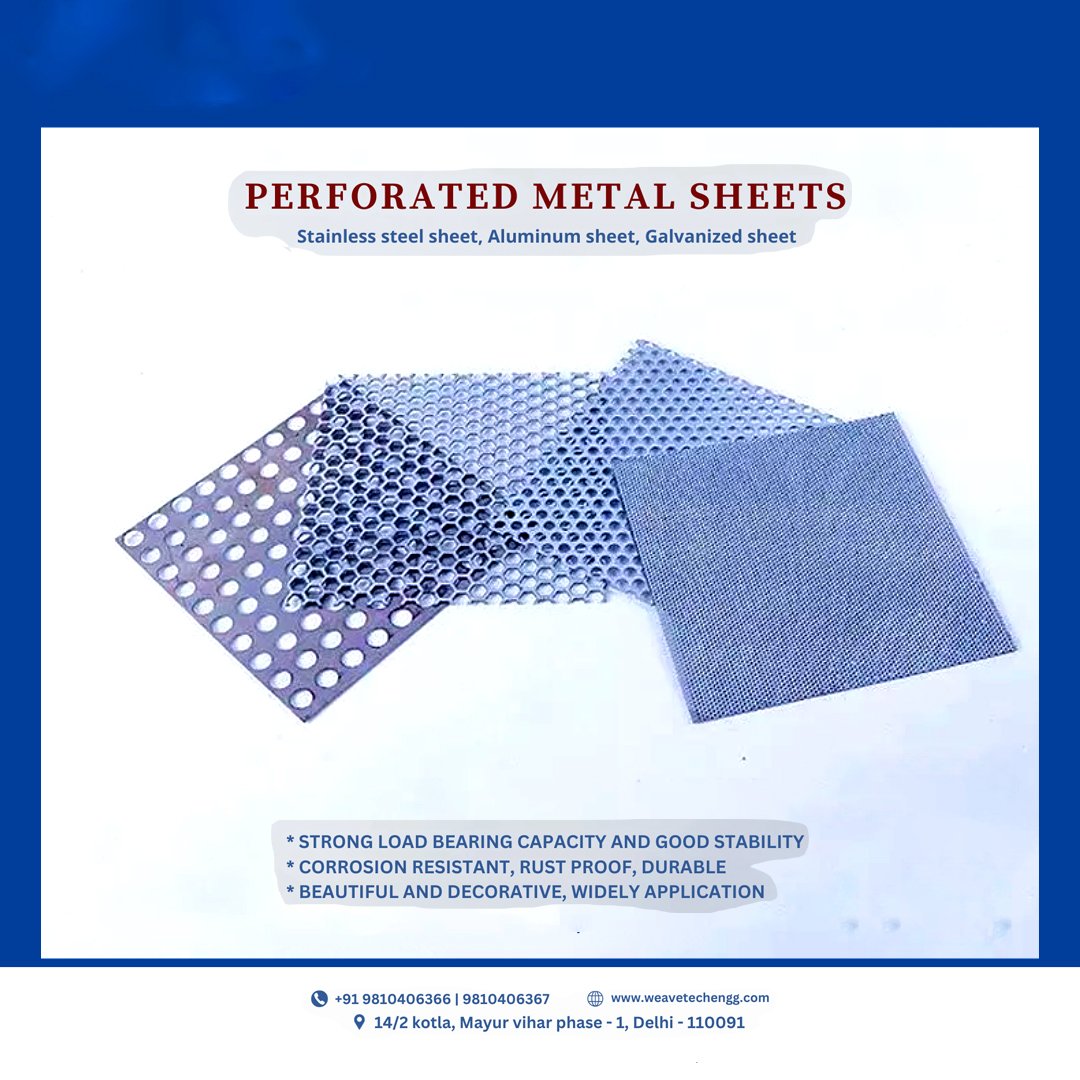

We’re Committed to Perforated Metal Sheets Excellence

Weave Tech Engineers is a leading company specializing in providing innovative engineering solutions across various industries. Established with a commitment to excellence, Weave Tech Engineers has built a reputation for delivering high-quality products and services tailored to meet the unique needs of its clients.

Learn More

Perforated Processed Sheet

Metal Sheets- Experience:27 Years

- E-mail:inquiry@weavetechengineers.com

- Phone:098104 06366

- Location:

Mayur Vihar Phase-1

New Delhi 110091

Perforated Processed Sheet: Revolutionizing Industries

Perforated processed sheets, a versatile and indispensable material, are transforming industries globally. These intricately designed sheets with precisely spaced holes offer unmatched functionality across various sectors, providing solutions for filtration, screening, protection, and decorative purposes. In this comprehensive guide, we delve into the myriad applications, manufacturing processes, material options, and advantages of perforated processed sheets.

Understanding Perforated Processed Sheets

Defining Perforated SheetsPerforated sheets, commonly made from metals like stainless steel, aluminum, or galvanized steel, undergo a specialized manufacturing process. The process involves precision punching or machining to create uniform perforations, enabling controlled passage of air, liquids, light, or sound. These holes can be round, square, slotted, or customized to meet specific requirements.

Applications Across Industries

The versatility of perforated processed sheets finds extensive use in diverse industries. From architectural designs to automotive components, from agricultural equipment to electronics, these sheets play a pivotal role. They're employed in HVAC systems, acoustic panels, food processing, pharmaceuticals, and even in aerospace engineering due to their lightweight and robust nature.

Manufacturing Processes of Perforated Processed Sheets

Punching Technique The most common method for creating perforations involves a punching process. This technique uses a specialized punching machine that precisely perforates the material, creating the desired pattern and hole size. The choice of punch and die shapes dictates the final appearance and functionality of the sheet.

Laser Cutting Method

Another method gaining popularity due to its precision is laser cutting. Utilizing a high-powered laser, this process accurately creates perforations while offering flexibility in design and intricate patterns. Laser cutting ensures clean edges and minimal material wastage, making it an environmentally friendly option.

Material Options and Their Advantages

Stainless Steel SheetsStainless steel perforated sheets are highly durable and resistant to corrosion, making them suitable for harsh environments. Their versatility lends well to architectural designs, industrial filters, and food processing equipment due to their hygienic properties.

Aluminum Sheets

Aluminum perforated sheets are lightweight and exhibit excellent conductivity. These sheets are commonly used in aerospace, automotive, and electronic industries for their thermal and electrical properties.

Galvanized Steel Sheets

Galvanized steel perforated sheets offer exceptional strength and rust resistance. They find applications in construction, agricultural machinery, and protective barriers due to their robustness.

Advantages of Perforated Processed Sheets

Enhanced Functionality Perforated sheets enable controlled airflow, light diffusion, sound absorption, and filtration. Their versatility makes them a preferred choice for architects, engineers, and designers seeking functional and aesthetic solutions. Customization and Design Flexibility

Manufacturers can customize perforated sheets according to specific

design requirements. Different hole shapes, sizes, and patterns offer

immense design flexibility, catering to unique project needs.

Durability and Sustainability

These sheets, crafted from durable materials, ensure long-term

performance and contribute to sustainability efforts. Their

recyclability and minimal environmental impact further reinforce their

value in modern industries.

Perforated processed sheets stand as a testament to innovation and adaptability in various industries. Their diverse applications, manufacturing techniques, material options, and undeniable advantages make them a critical component across sectors. Understanding their significance and leveraging their benefits can revolutionize design, functionality, and efficiency in countless applications.