Our Services

-

27 Years Experience

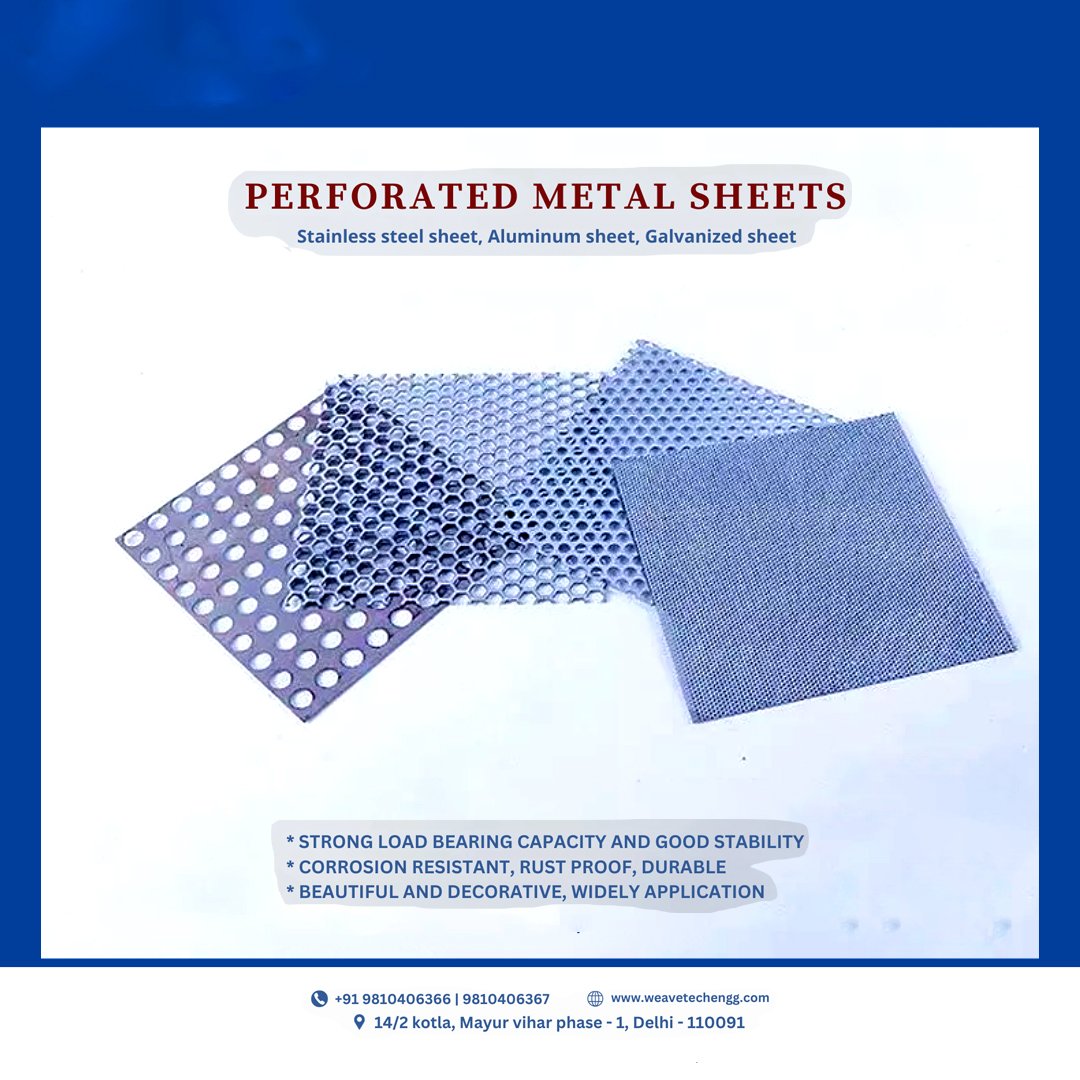

We’re Committed to Perforated Metal Sheets Excellence

Weave Tech Engineers is a leading company specializing in providing innovative engineering solutions across various industries. Established with a commitment to excellence, Weave Tech Engineers has built a reputation for delivering high-quality products and services tailored to meet the unique needs of its clients.

Learn More

Stainless Steel Perforated Sheets

Metal Sheets- Experience:27 Years

- E-mail:inquiry@weavetechengineers.com

- Phone:098104 06366

- Location:

Mayur Vihar Phase-1

New Delhi, 110091

Stainless Steel Perforated Sheets: Enhancing Versatility in Modern Applications

Stainless steel perforated sheets stand as a testament to the remarkable fusion of durability, functionality, and versatility in modern engineering and design. These sheets, meticulously engineered with precision-cut perforations, play an integral role in various industries due to their unique properties and adaptability.

Stainless Steel Perforated Sheets

Stainless steel, renowned for its exceptional resistance to corrosion and wear, undergoes a meticulous perforation process to form sheets that exhibit a pattern of holes or shapes. This process is conducted using advanced machinery and techniques, ensuring precision and consistency in the placement and size of the perforations. The result is a sturdy yet flexible sheet capable of enduring diverse conditions while maintaining its structural integrity.

Versatility in Applications

In architectural design, stainless steel perforated sheets are hailed for their aesthetic appeal and practicality. These sheets find extensive use in cladding, facades, balustrades, and sunscreens due to their ability to add a contemporary flair while offering durability against environmental factors.Industrially, these sheets serve as indispensable components in filtration systems, soundproofing equipment, machinery guards, and ventilation. Their perforated design allows for efficient airflow and sieving of materials, making them pivotal in optimizing various industrial processes.

Creative and Design Fields

In creative fields like interior design and artistic installations, stainless steel perforated sheets inspire innovation. They are employed in creating unique partitions, furniture, decorative panels, and lighting fixtures, allowing designers to infuse spaces with an elegant blend of functionality and style.

Key Features and Advantages

Stainless steel's inherent corrosion resistance and durability make perforated sheets a preferred choice in harsh environments. These sheets retain their structural integrity even when exposed to extreme temperatures, moisture, or chemical substances, ensuring prolonged longevity.

Customization and Design Flexibility

The ability to customize perforation patterns and sheet dimensions offers designers and engineers unparalleled flexibility in tailoring products to meet specific project requirements. This customization capability enhances creativity and functionality in various applications.Enhanced Functionality

The perforated design of these sheets allows for improved airflow, acoustic control, and light diffusion, contributing to enhanced functionality across multiple domains. The precise perforations enable optimal filtration and sieving, ensuring efficient operation in industrial processes.

In conclusion, stainless steel perforated sheets epitomize a harmonious blend of durability, adaptability, and aesthetic appeal. Their multifaceted utility across architectural, industrial, and creative spheres underscores their indispensability in modern applications.